DRY CRISTALIZADOR

DRY

ZEWATECH offers specific evaporators for each industry, and it’s always important and necessary to conduct a personalized study, analyzing management costs and the type of concentrate. The DRY models are designed for maximum concentration.

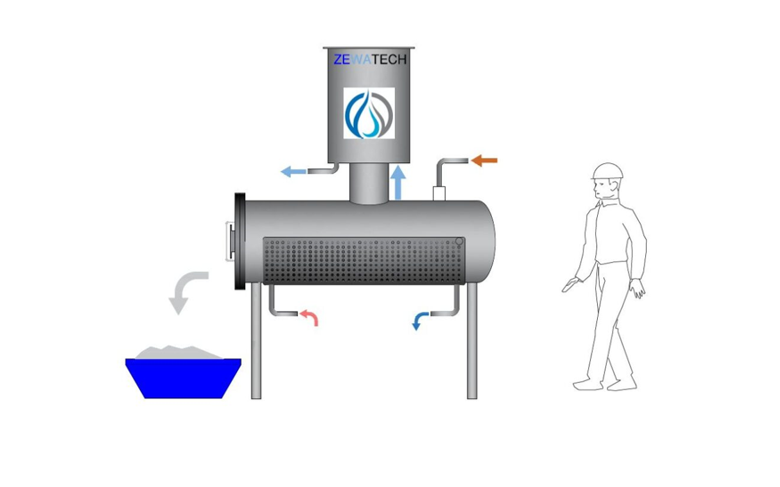

The functionality of the DRY evaporators is based on the vacuum evaporation phenomenon, which drastically reduces the final waste volume. The design aims to achieve the highest degree of heat transfer reliability with minimal issues related to dirt and fouling.

The industrial evaporation equipment consists of a loading tank, which is evacuated using a vacuum pump and heated using a heating jacket. The content is brought to boil at 35º, at which point it rises to the top of the DRY unit, and distillation occurs through an integrated heat exchange coil. The distilled water is recovered under optimal conditions, fully purified and of high quality, suitable for reuse in cleaning processes.

The result is clean distilled water and a concentrated dry residue inside the equipment that can be treated very efficiently and economically. This residue can be reduced by up to 98% in mass, depending on the contaminant load of the water being treated.

Like all models, these evaporators have been designed to operate continuously 24 hours a day with minimal supervision, requiring only electrical power and compressed air. The evaporator is fully automated and controlled by a microprocessor, allowing customers to easily adjust process parameters according to their needs and adapt to the characteristics of the contaminated water they want to treat.