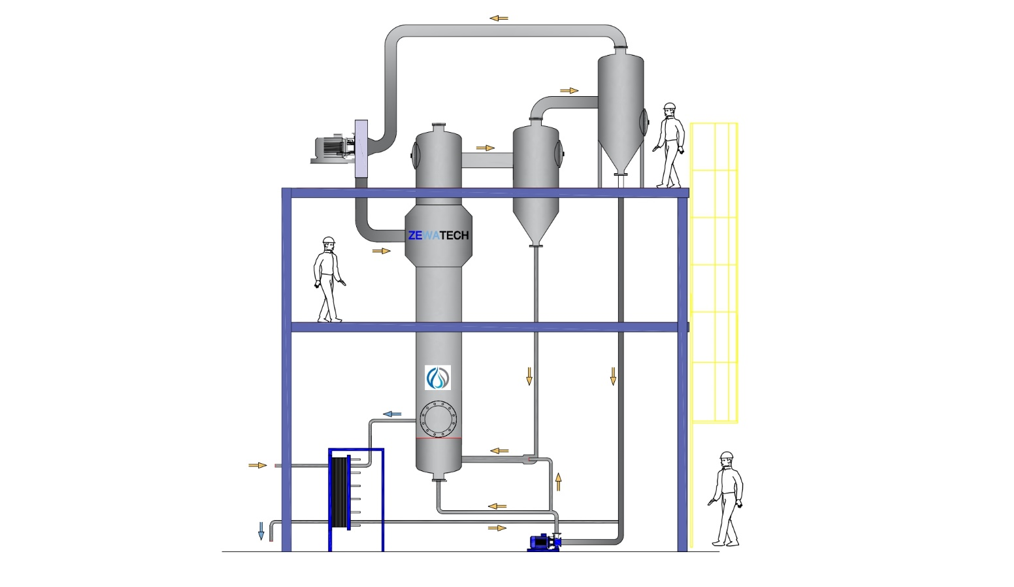

MVC-FB (VAPOUR COMPRESSION FLUIDIZED BED)

Mechanical Vapor Compression & Fluidized Bed

This evaporator configuration combines low energy consumption with high reliability, requiring minimal maintenance. The key to this type of evaporator is small ceramic balls that circulate through the shell-and-tube heat exchanger, creating an abrasive effect that prevents any type of fouling.

On the other hand, mechanical vapor compression provides an energy advantage. It involves using the same steam generated in the boiler to heat the wastewater. The water rises in the exchanger on the tube side, driven by a pump, where it heats up and partially evaporates. This same vapor is then compressed by a compressor, providing it with energy, and is introduced into the exchanger, descending on the shell side.

Furthermore, ZEWATECH technology has developed a system in which abrasive balls are recirculated to clean the exchanger while it is in operation, making maintenance easier and reducing problems related to fouling or dirt in the equipment.

Typical Applications:

- Biogas Plants

- Metallurgical Industry

- Petrochemical Industry

- Cosmetics & Pharmaceutical Industry

- Treatment of Osmosis Reject

Can treat more than

10.000

liters/day

consumption approx.

14

kW·h/m3

Boiling point

70ºC-90ºC