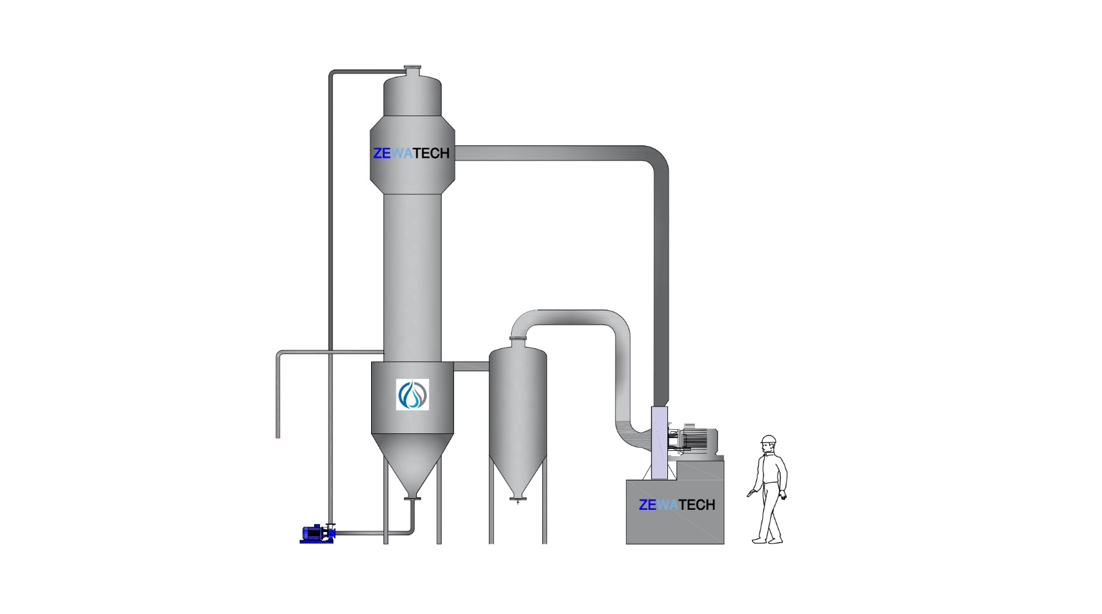

MVC-FF (VAPOUR COMPRESSION-FALLING FILM)

Mechanical Vapor Compression & Falling Film

This configuration combines the two most energy-efficient technologies: falling film and mechanical vapor compression.

The falling film technology is characterized by the vertical orientation of the heat exchanger, where water from the boiler descends through it on the shell side. It requires a pump with minimal head since it hardly needs to overcome any significant pressure loss.

This design offers significant advantages, such as high heat transfer efficiency. The cooling liquid is evenly distributed over a hot surface and flows downward as a thin and uniform film, enabling highly efficient heat transfer. It’s also a type of heat exchanger with a low risk of fouling because the liquid flows down on the heat exchanger’s surface, preventing mineral deposits or fouling on its walls.

On the other hand, mechanical vapor compression refers to the source of the fluid that provides the necessary energy for evaporation. It comes from the same steam generated in the boiler, which is compressed to receive the energy to exchange, and then circulates on the tube side, heating the water in the shell.

Typical Applications:

- Metallurgical Industry

Can treat more than

10.000

liters/day

Consumption approx.

12,5

kW·h/m3

Boiling point

70ºC-90ºC