OUR TECHNOLOGIES

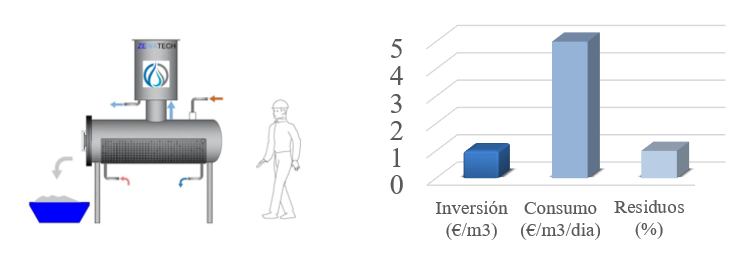

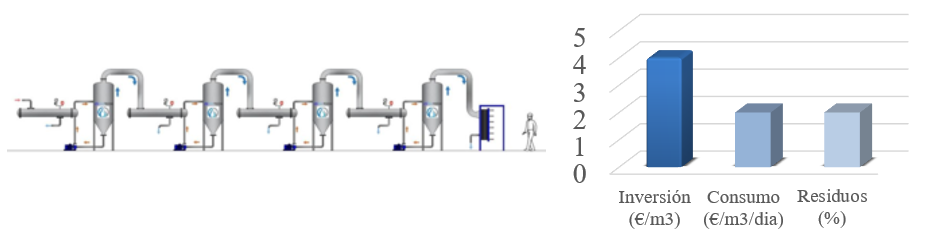

MVC. Mechanical vapour compression

MVC (Mechanical Vapor Compression) equipment utilizes the mechanical compression of vapor generated by an aspirator or compressor. These systems are recommended for treating relatively simple water sources with low energy costs.

They are particularly suitable for use in metallurgical industries where there are no chlorides or other salts present, and scaling is not a concern. MVC technology is capable of treating more than 10,000 liters per day.

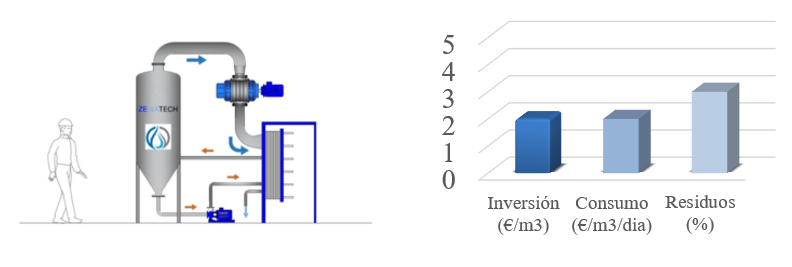

VT. Vertical simple

VT (Vertical simple) equipment features a vertical boiler and forced circulation through a heat exchanger. These systems are recommended for water treatments where a certain level of waste concentration is required, provided that the waste is in liquid or pumpable form.

They are suitable for treating drilling fluids, oils, or other liquid waste streams with concentrations ranging from 5% to 25%.

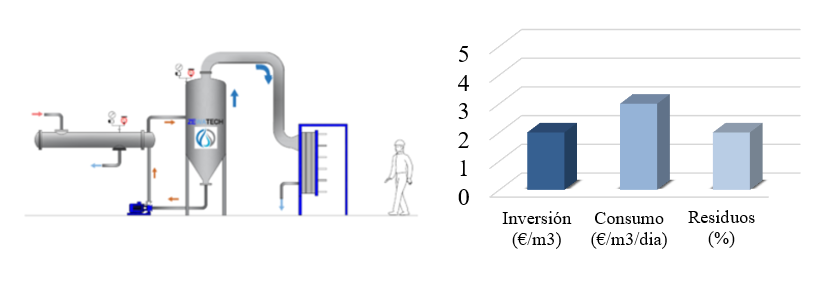

VT 2E. Vertical double

VT 2E (Vertical Tube, Double Effect) equipment features two vertical double-effect boilers, where the energy from the first boiler is used to heat the second one, resulting in reduced energy consumption.

These systems can handle flow rates exceeding 10 m3/day and can be supplied with either steam or hot water.

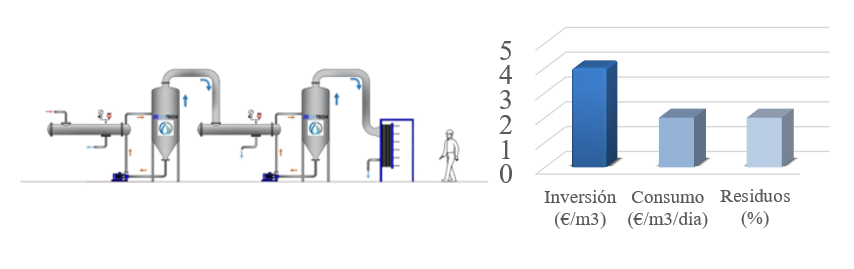

VT 3E. Vertical triple

VT 3E (Vertical Tube, Triple Effect) equipment features three vertical triple-effect boilers, where the heat from all three boilers in series allows for very high energy efficiency.

These systems can handle flow rates exceeding 30 m3/day and can be supplied with either steam or hot water at a very low energy cost.

VT-R. Vertical con rascador

VT-R equipment features a vertical boiler with an internal scraper that prevents the buildup of solid materials on the boiler walls, allowing for higher waste concentration. These systems enable automatic solid discharge.

They provide complete drying and automatic extraction for up to 10,000 liters/day.

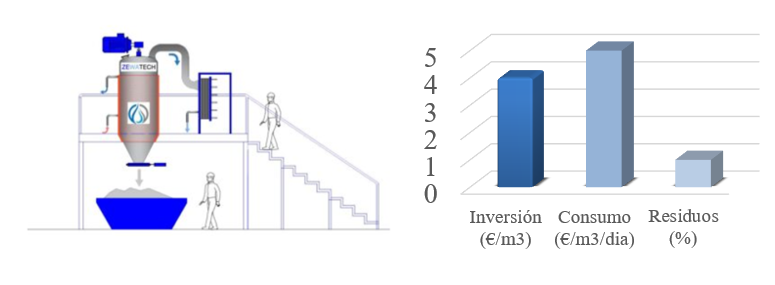

DRY

DRY equipment consists of crystallizers with a horizontal boiler designed for treating low flow rates using a heating jacket. These systems enable high concentration or drying of waste materials to complete dryness.

They provide complete drying of the waste material and manual extraction for up to 3,000 liters/day.