FLUIDIZED BED

FLUIDIZED BED

Fluidized bed technology is commonly used in the industry to enhance heat transfer efficiency and reduce maintenance costs. Heat exchangers are devices designed to transfer heat from one medium to another and are frequently used in industrial evaporators involving fluids and gases.

This evaporator configuration combines low energy consumption with high reliability and requires minimal maintenance. The key to this type of evaporator lies in the use of small ceramic balls that circulate within the shell-and-tube heat exchanger. These balls have an abrasive effect that prevents the formation of deposits.

During regular operation, wastewater can leave sediments or deposits on the inner surfaces of the heat exchanger, reducing heat transfer efficiency and increasing maintenance costs due to the need for frequent cleaning. Ceramic balls are used to effectively remove these deposits, thereby preventing costly maintenance.

Thanks to ZEWATECH’s technology, these balls circulate within the heat exchanger and its circuit without affecting other equipment, thus safeguarding the integrity of these components.

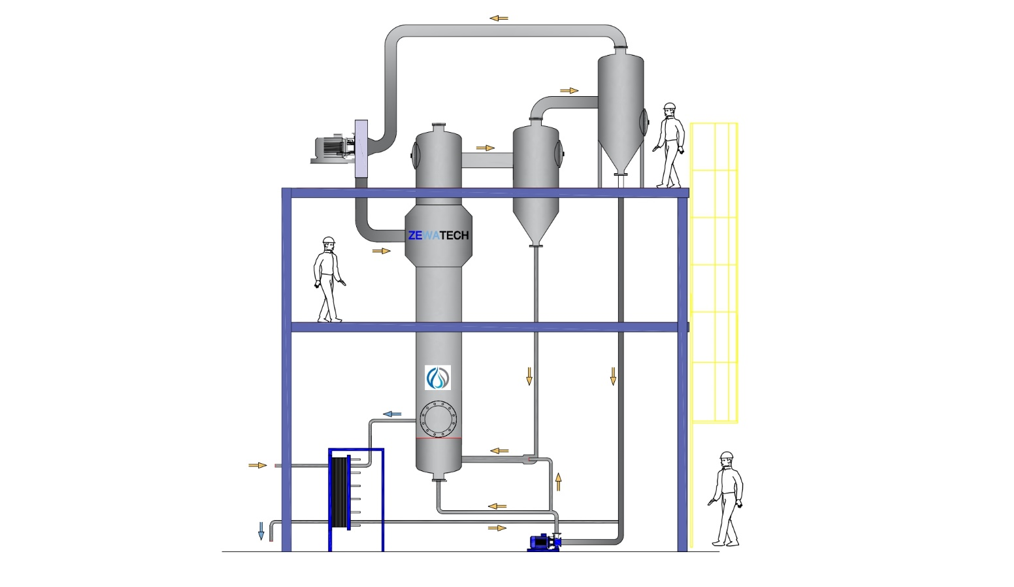

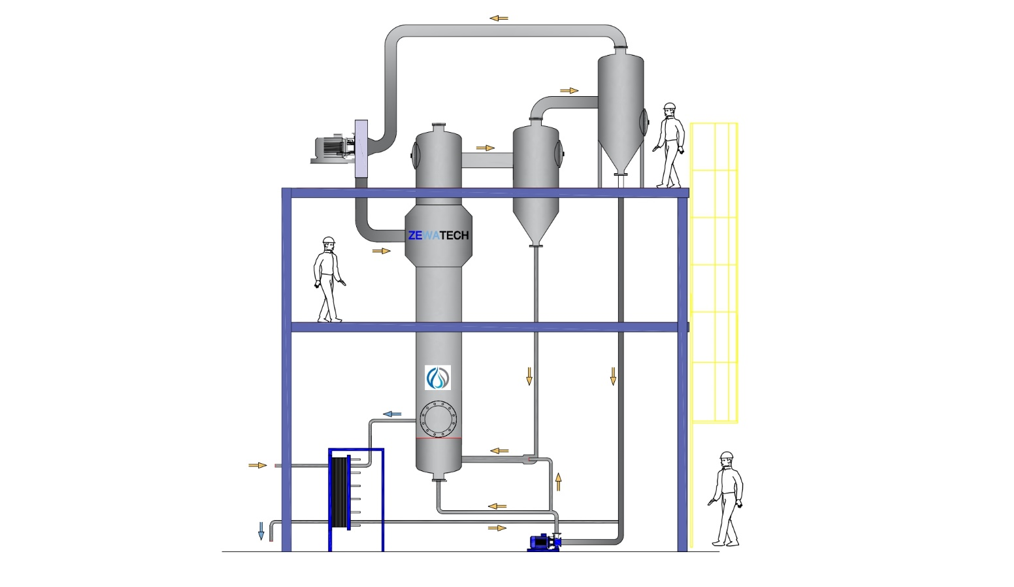

On the other hand, mechanical vapor compression offers advantages in terms of energy efficiency. In this process, the steam generated in the boiler is used to heat the wastewater. The water is pumped into the tube-side of the heat exchanger, where it is heated, and a portion of it evaporates. Then, the resulting vapor is compressed by a compressor that provides additional energy before introducing it into the shell-side heat exchanger, where it descends and continues the process.

layout