Serie VP-R

VT S (steam/hot water feed, etc.)

The evaporator from the VP-S series has the capacity to perform an efficient and potentially reusable distillation, provided that there are no DISSOLIDATED SALTS prone to INCRUSTATION and a concentrate, solid or semi-solid with a minimum water content.

These evaporators have been designed to treat large effluent flows with a suspended solids content of less than 20% or to treat water used as service or function water and industrial degreasing processes.

The specific capacity produced in one hour per unit is between 10 and 500 L/h.

The evaporator is fully automatic and regulated with a microprocessor that allows customers to easily change the process parameters depending on their needs and to adapt them to the characteristics of the polluted water they want to treat.

What characterises this evaporator is its great versatility and its adaptation to any large quantity of process water, especially those with a low quantity of solids in suspension or with densities similar to that of water.

As with all models, the evaporators are designed to operate continuously 24 hours a day, with minimum supervision, with only electrical power and compressed air requirements.

This evaporator is excellent for use in emulsions and industrial cleaning and degreasing processes, as its characteristics are defined by an internal coil as well as a steam current inlet.

As with all models, the evaporators are designed to operate continuously 24 hours a day, with minimum supervision, with only electrical power and compressed air requirements.

Their specification is defined by a heat pump system with heating coil and internal scraper to prevent solid material from sticking to the surface of the kettle and the inlet flow is in a vapour state.

These equipments are dimensioned and designed according to the application and depending on the special characteristics of each project.

For further information please contact our engineering department.

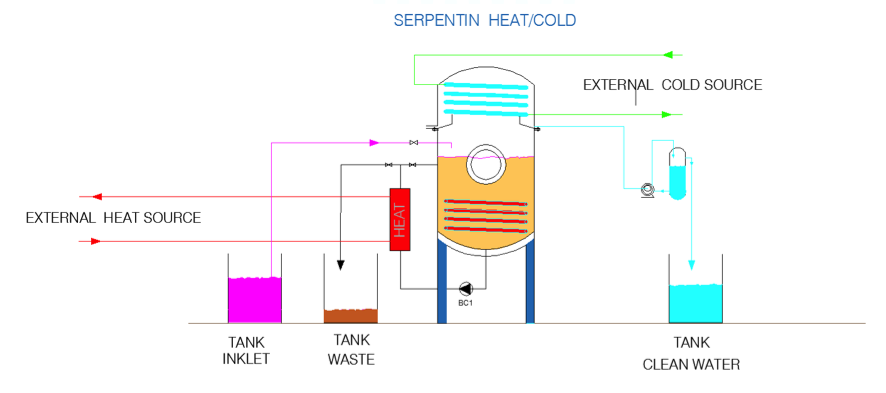

DIAGRAM

SPECIFIC OPTIONS

- Automatic extraction

- Single / Double / Triple effect

- Automatic cleaning

- Internal scraper

- Construction material STAINLESS STEEL 316-SUPERDUPLEX-SANYCRO-Stainless steel

- Thermal oil / steam water

- Cooling tower

- Vertical vs. horizontal boiler

- Automatic defoamer dosing and control system

- Higher chassis for waste discharge

- Other electrical power supplies available

- Special projects

Equipment sized according to the application and special characteristics of the project.

Consult our engineering department